-

Pompa di Calore ETS

- Metering Systems

-

Gas Valves

Gas Valves

Gas Valves -

Water Valves and Bibcocks

Water Valves and Bibcocks

Water Valves and Bibcocks - Industrial Ball Valves

- Motorised Valves

Robex Vt

Triple valve

Outstanding triple valve: ball valve, check valve and two side ports. Designed to give a solution to professional and industrial users who intend to have a single product rather than three different ones. It combines the characteristics of robustness and reliability of the Omega series with the reduced pressure drops of the Valstop series of check valves.

Material specification

Approved to EN 13828

COMPONENT | MATERIAL | DESCRIPTION | ||

|---|---|---|---|---|

1 | BODY | CW 617 N UNI EN 12165 | FORGED | |

2 | END ADAPTER | CW 617 N UNI EN 12165 | FORGED | |

3 | BALL | CW 614 N UNI EN 12164 | MACHINED, NICKEL-CHROME | |

4 | BALL GASKETS | P.T.F.E. | PURE | |

5 | STEM | CW 614 N UNI EN 12164 | MACHINED | |

6 | THRUST WASHER | P.T.F.E. | PURE | |

7 | O-RINGS | ELASTOMER | SUITABLE FOR USE WITH WATER | |

8 | HANDLE /T-HANDLE | AL UNI 5076 | PAINTED | |

9 | SELF-LOCKING NUT | 8G STEEL | ZINC-PLATED | |

10 | JUMPER GASKET | ELASTOMER | SUITABLE FOR USE WITH WATER | |

11 | JUMPER | POLYMERIC RESIN | MOLDED | |

12 | JUMPER GUIDE | POLYMERIC RESIN | MOLDED | |

13 | SPRING | STAINLESS STEEL AISI 302 | NORMALIZED | |

14 | CAPS | NYLON | MOLDED | |

15 | CAP GASKETS | ELASTOMER | SUITABLE FOR USE WITH WATER |

Characteristics

END CONNECTIONS | Ends threaded to UNI ISO 228/1. |

USES | Hydraulic systems with hot and cold water. Heating systems. Compressed air. Non-aggressive fluids compatible with the components of the valve. |

INSTALLATION POSITION | ROBEX-VT triple valves can be installed in any position (vertical, horizontal, oblique). |

WORKING PRESSURE | Min 0,05 bar (for check valves). |

TEMPERATURE LIMITS | From -15°C to + 100°C. |

CRACKING PRESSURE | Min 0,025 bar (25 cm water column). |

CRACKING PRESSURE | Min 0,05 bar (50 cm water column). |

ROBEX - VT TRIPLE VALVE | ROBEX-VT triple valves are the result of combining OMEGA ball valves, heavy full bore valves, VALSTOP check valves, heavy full bore valves with extremely reduced loss of head, and two plugged side outlets, one upstream and one downstream of the jumper. |

NOTE | According to UNI EN 13828 in presence of water which could be aggressive for brass alloy, as agree with UNI EN ISO 6509 standard, is necessary the DZR brass alloy. The manufacture is available on request. |

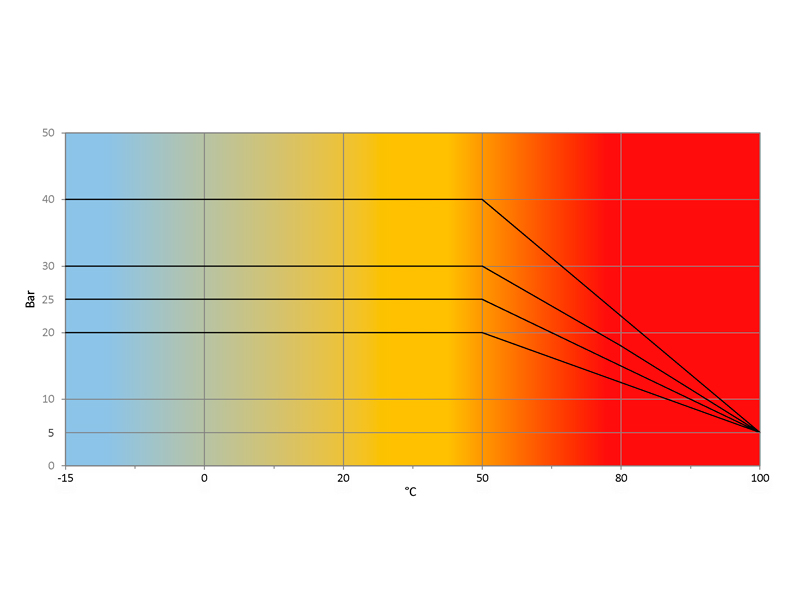

Pressure/temperature diagram

(tested with water)

Loss of head diagram

(tested carried with water)

Download

Robex Vt 712.19 KB